The excitement with DTF (Direct to Film) technology is still growing in the world of modern digital printing. There are no limits to what DTF printing can do or how creative it can be. But, there is one question that keeps many fans and professionals interested: Can DTF print on wood?

We explore the field of DTF printing on wood surfaces in this study, revealing the opportunities and possible drawbacks for anyone attempting to combine these two vibrant worlds. Get ready to learn the mysteries around this fascinating blend of technology and environment.

DTF Printing on Wood Canvases Possible?

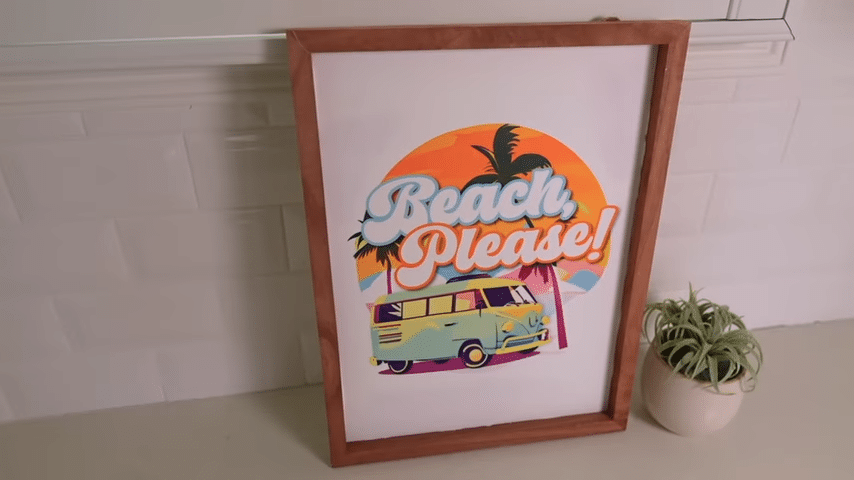

Yes, DTF (Direct to Film) printing can be used successfully on wood surfaces. Known for its flexibility, this dynamic printing method makes it possible to reproduce complex and colorful images straight into wood with amazing results.

Prepare the wood surface and use suitable DTF inks to achieve wood application adherence, color brightness, and durability. When it comes to preserving the organic beauty and texture of wood, DTF printing enables companies and craftspeople to explore new creative possibilities. It can be for branded wooden goods, customized wooden décor, or artistic masterpieces on wooden canvases.

Applying DTF Transfers on Wood Surfaces

I can guide you through the process of applying DTF transfers on wood surfaces:

- Gather Your Materials: Start by putting together all of the required supplies. The wooden surface you want to print on, a Teflon sheet, an easy press (like the Cricut Easy Press 3) and of course your DTF transfer is what you need.

- To preheat the Easy Press, turn it on to 345 degrees Fahrenheit and let it run until the appropriate degree of heat is reached.

- Moisture Control: Lightly run the hot simple press over the hardwood surface before to putting on the DTF transfer. This step helps remove excess moisture, ensuring better adhesion.

- Positioning the DTF Transfer: Carefully place the DTF transfer on the wood where you want the pattern to stick out. Give it some time to make sure it is precisely aligned.

- Apply pressure: After positioning the DTF transfer, apply a little pressure on the wooden surface. Take care not to exert too much pressure as this might harm the wood. Keep it in place for around twenty seconds.

- Step of Cooling: Allow the transferred design to cool completely. In order to make sure that the pattern sticks to the board firmly, this step is essential.

- Film Removal: After the design has had time to cool, begin very gently removing the film off the wooden surface. Proceed cautiously and gently to avoid lifting the design or causing harm to it.

- Handling Problems: Don’t worry if the film starts to tear up during the removal process. Just apply heat again for a little while, and then carry out the removal procedure once again.

- Wrinkle Smoothing: To get a perfect finish, smooth out any creases or defects in the transferred pattern using your fingertips or a squeegee.

- Final Adhesion: Press the pattern for a further 15 to 20 seconds while covering it with a Teflon sheet or parchment paper. This last stage helps to fix the pattern firmly into the wood surface and guarantees correct adherence.

- Project Finished: Congratulations! Once you’ve finished these procedures, you’ve created an amazing DTF transfer to the wood surface. Your project is now ready to showcase its full-blown design.

Following these steps with precision will yield impressive results, allowing you to unlock a world of creative possibilities with wood DTF printing.

DTF Ink and Wood Compatibility

Understanding the compatibility of DTF ink and wood is essential for obtaining vivid and durable results when DTF (Direct to Film) printing on wood. Here’s a deeper analysis of this key element:

- Ink Types and Formulations: DTF inks are available in a variety of formulations, including solvent-based, water-based, and UV-curable. Choosing an ink type that works well with wood surfaces is crucial. For example, we can use water-based DTF inks since they stick to wood nicely without causing any harm to the substance.

- Adhesion to Wood: Making sure the DTF ink sticks to wood surfaces properly is the main challenge. Natural oils or uneven textures in certain woods might affect adherence. You can fix this problem by using an ink that sticks well to wood and is made for that purpose.

- Color vitality: When applied to wood, DTF inks ought to preserve color vitality. To get high-quality results, use inks that produce consistent and brilliant colors on wood, since wood absorbs ink differently than paper or cloth.

- Durability and Resistance: DTF ink on wood should withstand parameters such as moisture, UV light, and abrasion. This ensures that the printed pattern will last a long time, particularly if you’re going to utilize the wood product outside or in high-wear environments.

- Compatibility Testing: It’s a good idea to carry out compatibility testing before to starting a large-scale DTF printing project on wood. Here, several ink formulas and settings are tested on a sample piece of wood to see which combination produces the greatest adherence, color, and durability.

- Surface Preparation: A well-prepared wood surface could enhance the compatibility of ink. Sanding, washing, and putting a DTF primer or coating could render ink more responsive.

- Maintenance Considerations: It’s crucial that you take into account the maintenance needs for the wood-printed product, depending on its intended usage. Make sure the DTF ink you use on wood can tolerate normal wear and tear and is resistant to ordinary cleaning agents.

To sum up, the compatibility of DTF ink with wood is essential to getting good and eye-catching prints when printing on wood surfaces. Choose the best ink, verify compatibility, and prepare the wood surface to maximize DTF printing on wood’s creative potential and ensure long-lasting patterns.

Applications and Creative Possibilities

Direct-to-film (DTF) printing on wood offers a plethora of creative opportunities and varied uses. Here’s a glimpse of the stimulating possibilities it offers:

- Personalized Décor: You can create bespoke wood décor items like photo frames, wall art, and signage with DTF printing. To mark significant events, include names, dates, or thought-provoking quotations.

- Branded Merchandise: Companies can mark their goods on wooden boxes as well as promotional items like coasters, pens, and keychains by using DTF on wood. It’s a fantastic method to make marketing materials that stick in the mind and increase brand exposure.

- Artistic Creations: On wooden canvases, artisans and artists can display their inventiveness. DTF printing is ideal for producing one-of-a-kind sculptures and artwork because it allows for complex and vivid patterns.

- Custom Furniture: Give new life to furniture by adding custom designs to wooden surfaces. Imagine a handmade wooden chair with colorful embellishments or a unique dining table with a DTF-printed design.

- Wooden Signage: DTF-printed wooden signs are eye-catching and adaptable, perfect for events or enterprises. You can made storefront displays, event banners, and directional signs.

- Personalized presents: You may create meaningful and enduring presents using DTF procedure on wood. Create customized cutting boards, family name signs, or engraved plaques as unique wooden presents.

- Home Improvement: Enhance your home with DTF-printed wooden elements. Make gorgeous accent walls, ornamental panels, or elaborate designs on hardwood floors.

More Use Cases

- Interior Design: Customized room dividers, headboards, and cabinets are just a few examples of the distinctive timber pieces that interior designers can use DTF printing to add into their designs.

- Artistic Reproductions: Create eye-catching and aesthetically pleasing artwork by meticulously and accurately reproducing well-known paintings or old photos on wood.

- Event Decor: Wooden props and decorations for weddings, parties, and business gatherings can be created with DTF printing. Make centerpieces for tables, backgrounds with themes, and more.

- Architectural Applications: In both home and business environments, DTF-printed wood can be used for architectural elements. Consider detailed wooden ceiling tiles, panels, and columns.

- Custom Packaging: Create distinctive wooden packaging for high-end and handcrafted goods. DTF printing improves the look of products, from engraved wine bottle cases to hardwood jewelry boxes.

- Educational Materials: Teachers and educators can use DTF printing on wood to create engaging educational materials, such as interactive wooden puzzles and history timelines.

- Sporting goods: Tailor wooden sports equipment to the likes and styles of players, such as tennis rackets, baseball bats, or golf clubs.

DTF printing on wood is a flexible and appealing canvas for expressing creativity and personalizing home décor, company branding, and more. The only thing stopping it from becoming more innovative and customizable is one’s creativity.

Future Developments and Trends

Promising advancements and trends in DTF (Direct to Film) printing on wood are expected to further define this cutting-edge printing technique in the years to come.

Advanced Ink Formulations: DTF ink formulations are expected to continue to progress. It is likely that manufacturers will carry on refining and developing inks to provide better durability, color vibrancy, and adherence on wood surfaces. Even more amazing and durable outcomes will be possible.

Extended Color Gamut: Upcoming DTF printing technologies could provide a more extensive color gamut, enabling a greater variety of vivid and personalized hues. For wood printing projects, this will open up even more creative possibilities and customisation choices.

Precision and Detail: As technology advances, DTF printers will accurately reproduce elaborate patterns and delicate features. For creative and aesthetic purposes, this will make DTF printing on wood even more alluring.

Integration with Smart Devices: Nowadays, printing technology is characterized by tendencies toward automation and connectivity. Future developments might see DTF printers interface with software and smart devices, improving user ease and expediting the design-to-print process.

Other Aspects

Focus on Sustainability: The printing sector is becoming increasingly conscious of sustainability issues. To appeal to customers who care about the environment and companies trying to lower their carbon footprint, expect to see a focus on eco-friendly DTF inks and procedures.

Adaptation On Demand: Printing and customizing materials on demand will keep becoming more and more popular. Businesses can offer customized wood goods with short turnaround times.

Partnership with Other Industries: DTF printing on wood will work more and more with sectors including furniture production, fashion, and interior design. By combining wood and DTF-printed components, this synergy will produce something special and hybrid.

Integration with Augmented Reality (AR): Combining AR technology with DTF-printed components could result in immersive and interactive experiences. Users of AR applications can communicate creatively and differently with DTF-printed wood goods.

Market expansion: As more people become aware of DTF printing methods on wood, more industries will join the market. This might include wooden architectural elements, luxury items packaged in unique wooden ways, and more.

Trends in DIY and Crafting: As DTF printing technology becomes more widely available, there might be a rise in the number of one-of-a-kind and customized woodworking projects.

Conclusion

To sum up, there is no denying the amazing potential of Direct to Film (DTF) printing on wood. This printing technique keeps pushing the creative envelope as technology develops, providing many possibilities for customized branding, décor, and artistic expression on wood surfaces.

With advances in ink formulas, accuracy, and sustainability, DTF printing on wood will change the printing and woodworking sectors, enabling innovation and personalization. The combination of DTF printing and wood will no doubt enthrall and excite as we go, opening us a universe of creative possibilities.

FAQs

DTF printing works on many wood kinds, however some need pretreatment or coating. Hardwoods like oak and maple are often preferred due to their smooth surfaces.

Ink quality, UV light exposure, and environmental circumstances affect DTF prints on wood lifetime. Even in outdoor environments, DTF prints can persist for years if they are properly protected and cared for.

Generally speaking, DTF inks made for wood applications are safe and do not damage the wood. They are designed to stick firmly without breaking down or harming anything.

Yes, we can use DTF-printed wood outside, but to keep the print safe from the sun and moisture, use UV-resistant inks and appropriate sealants.

Keeping the surface dry and clean is part of maintenance. To clean, use a soft cloth and a mild cleanser. Avoid aggressive chemicals and abrasives that might harm the print or wood.

Certainly. DTF printing is a popular option for personalized photo gifts and décor. It reproduces high-resolution images with amazing clarity and color fidelity on wood.

You’ll need a DTF printer and a heat press. Some wood surfaces can require additional preparation, such as sanding or coating, depending on the printer and ink used.

Ashley Wang is a skilled sales manager with knowledge in DTF printing. She presently works for ShenLan Digital, a reputable DTF printer maker. Ashley is the best person to offer advice on selecting the most suitable DTF printer because she has tested a lot of them. She launched DTFPrinterSchool to educate individuals and organisations about DTF printing technology, providing her expertise and observations on the most recent advancements in the sector. Ashley is an invaluable resource for businesses and individuals wishing to invest in DTF printing technology because of her expertise and experience in the industry.