In recent years, DTF printing has become a popular alternative to conventional fabric and garment printing. But experts keep arguing about whether or not DTF powder should be used during the printing process. While some vouch for its ability to produce prints of a high quality, some claim that it is unneeded and may result in problems like clogging and messiness. In this blog post, we’ll talk about the pros and cons of using DTF powder in the printing process, as well as other ways to make good prints without it.

Can I use DTF without powder?

Yes, it is possible to print directly to film (DTF) without needing DTF powder. In place of the powder, you might coat the transfer sheet with glue prior to printing. Like the powder, this adhesive provides a sticky surface for ink to attach to, reducing smearing and bleeding during printing. Using adhesive instead of DTF powder might result in a cleaner printing process with less waste. It’s crucial to weigh the pros and downsides of utilizing DTF with or without powder before choosing a technique for your printing job.

What is DTF powder?

The direct-to-film printing technique requires the use of DTF powder, also known as direct-to-film powder. It is a finely ground powder made from cornflour or potato starch.

It is used to make the film or transfer sheet stickier before printing. During the printing process, the powder helps the ink cling to the sheet and avoids smudging or spreading.

Yamation DTF Powder Adhesive White 500g

- Strong Adhesion and Reliable Fastness

- Uniform Particle and Soft Feel

- Bright Colors and Vivid Pattern

- Widely Application and Easy Storage

- Wide Compatibility DTF Powder

- Bright Colors & High Quality

- Waterproof & High Durability

- Reliable After-sales Support and 100% Money Back

Welcar DTF Powder Adhesive 500g

- Super Adhesion

- Vivid Color

- Suitable for all DTF Printer and All sublimation Printer

- Easy to storage & Long Lasting

- Print On All Fabrics

- No Clogging

- Durable & Brightly Colored

- 60 days risk-free warranty

- Wide Compatibility

- Print on All Fabric All Color

- Waterproof and washable, durable

- Softening, Brightening

- Bright Color & Clear

- Double Side & Jam Free

- No Fade & Washable

- Wide Application

Benefits & Drawbacks

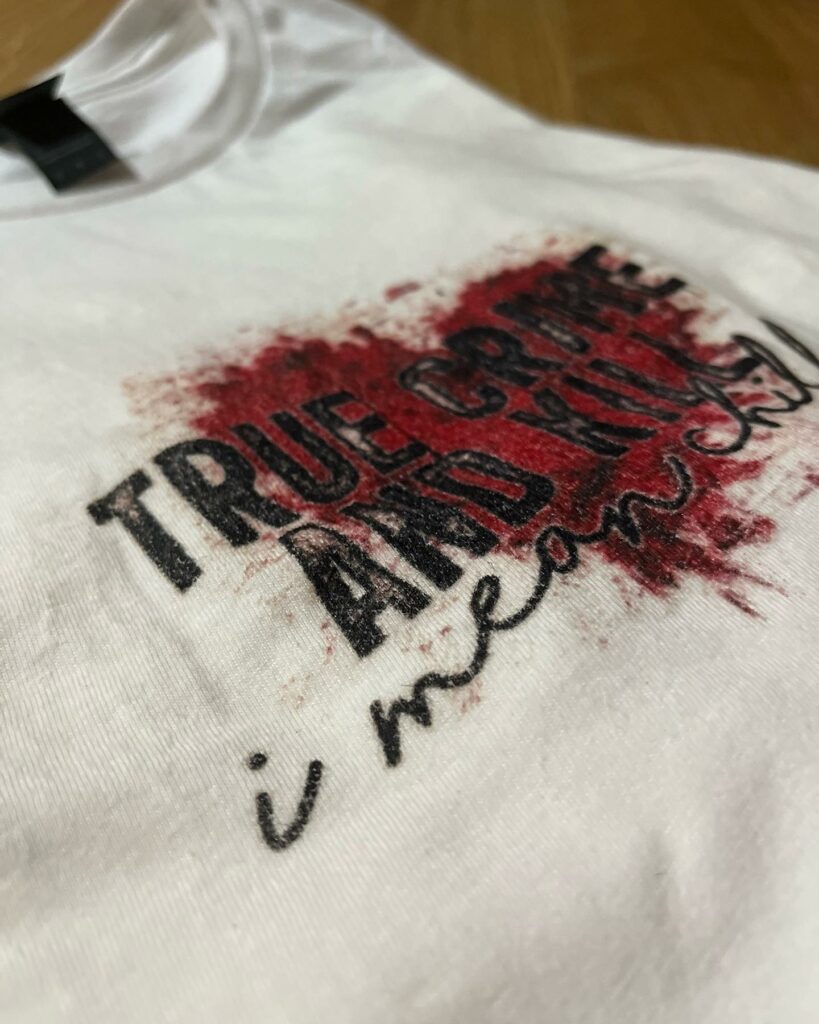

Utilising DTF powder has advantages such as better print quality, more vibrant colours, and higher print durability. Also, using DTF powder can help keep problems like bleeding or smudging from happening when writing on certain fabrics.

However, using DTF powder has disadvantages as well. One big problem is that the powder stuck in the printer’s print heads. This causes writing mistakes and more repair costs. Also, DTF powder produces excessive waste and are messy to deal with.

DTF printing without powder

DTF printing without powder is an alternate technique that is becoming more and more well-liked among experts. This technique includes coating the transfer sheet with adhesive prior to printing, as opposed to employing DTF powder to provide a sticky surface for the ink to attach to. The adhesive sticks the ink to the sheet like the powder, eliminating smudging and bleeding.

Using this approach has the benefit of not using DTF powder, which can be messy to deal with and can clog printer print heads. This procedure also produces less trash and cleaner printing.

However, utilising DTF without powder has certain drawbacks as well. Adhesive may be more costly than DTF powder, which can raise printing costs. Also, this method may not be as good as DTF powder at keeping the ink from smudging or spilling, which can lead to lower-quality prints.

The debate: DTF Printing with or without powder?

Arguments in favor of using DTF with powder:

- Better print quality: According to several professionals, employing DTF powder produces prints with better colour vibrancy and durability.

- Improved adherence: The powder produces a sticky surface that aids ink adhesion to the sheet and minimises smudging or bleeding when printing.

- Cost-effective: DTF powder is often more economical than other kinds of adhesives, making it a more viable choice for certain professionals.

- Method used traditionally: DTF printing with powder has been the go-to technique for many years and has been proven effective.

Arguments against mixing powder and DTF:

- Messy and wasteful: Working with the powder can be messy. It can make a lot of waste, which can be a problem when printing.

- Clogging: DTF powder can get stuck in the printer’s print head. It can cause writing mistakes and cost more to fix.

- Concerns about the environment: Some practitioners worry about the effects of using DTF powder. It can contain dangerous chemicals and add to pollution.

Different opinions and experiences of various DTF practitioners:

Different practitioners have different ideas about whether or not to use DTF powder. While some vouch for its efficacy and won’t try any other approach, others have had success with other approaches such employing sticky sprays or transfer tape.

While some practitioners like to use DTF powder for all of their prints, others only use it for certain prints, such as those with intricate or high-detail patterns. The choice to employ DTF printing with or without powder ultimately comes down to personal preferences and the particular requirements of each printing job.

My Experience on DTF Printing without powder

In order to print on fabrics or other surfaces, DTF entails applying ink from a transfer sheet. The transfer sheet is coated with DTF powder, also known as hot melt adhesive powder, to assist the ink attach to the cloth during printing. For this reason, the powder must be printed underneath every print area.

While there are DTF printer without powder in the market, my experience shows that the prints produced without the powder do not hold up well. This is because without the powder’s adhesive qualities, the ink may not cling to the cloth correctly and could smudge or bleed while being printed. This can lead to prints that aren’t as good and won’t last as long.

It’s vital to remember that hot melt adhesive powder is the technical name for the white powder we use in DTF printing. This powder encourages ink adherence to the transfer sheet and ensure effective transfer to the cloth.

To get high-quality, long-lasting prints while employing DTF printing technology, it is essential to utilize DTF powder. The powder’s sticky characteristics help the ink stick to the cloth, which improves print quality.

Tips for using DTF printing technology with or without powder

Tips for powderless or powdered DTF printing:

- Use transfer paper and ink of the highest quality that are suitable for your printer and the kind of cloth you’re printing on.

- When adding DTF powder or adhesive on the transfer sheet, carefully follow the manufacturer’s instructions.

- Before printing, make sure the print heads on your printer are clear and in excellent shape.

- To make sure that the ink is being applied at the proper pressure and temperature, adjust the printer’s settings.

- To ensure that the design is precisely printed into the cloth, be thorough and careful during printing.

Safety precautions for DTF powder:

- Inhaling or ingesting DTF powder can be hazardous; therefore, you should wear protective devices such as mittens and a respirator when handling it.

- Keep DTF powder in a cool, dry place that doesn’t get direct sunlight or heat.

- To prevent excessive dust and possible print head clogging, use care while adding DTF powder to the transfer sheet.

- Get rid of any extra DTF powder the right way and according to local laws.

Following these suggestions and taking care will ensure effective DTF printing with or without powder and reduce safety hazards.

Conclusion

In conclusion, DTF printing technique is adaptable and popular for transferring patterns to textiles and other surfaces. Whether you use DTF powder or another technique, it’s crucial to weigh the pros and downsides and follow best practices to get good prints.

It is possible to print do powderless DTF printing, however the prints may be of inferior quality and less robust than those made using DTF powder.

FAQs

Yes, it is possible to use DTF printing without powder by using an alternative adhesive layer on the transfer sheet.

We use DTF powder to make the transfer sheet sticky to help the ink attach to the cloth during printing. This encourages ink’s adherence on DTF Film.

Using DTF powder results in prints that are cleaner and produce less trash.

DTF powder is sticky and difficult to apply. Inhaling or ingesting it may be hazardous, so handle it carefully.

Ashley Wang is a skilled sales manager with knowledge in DTF printing. She presently works for ShenLan Digital, a reputable DTF printer maker. Ashley is the best person to offer advice on selecting the most suitable DTF printer because she has tested a lot of them. She launched DTFPrinterSchool to educate individuals and organisations about DTF printing technology, providing her expertise and observations on the most recent advancements in the sector. Ashley is an invaluable resource for businesses and individuals wishing to invest in DTF printing technology because of her expertise and experience in the industry.