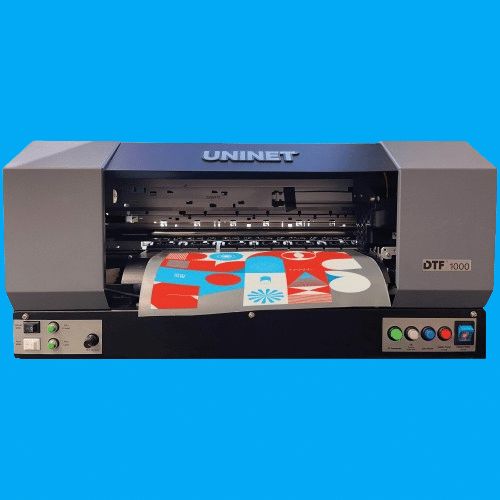

The Uninet 1000 is a reliable companion for DTF printing fans, where every ink stroke creates vibrant images. However, a persistent challenge has cast a shadow on the pristine white canvas – the mysterious transformation of white dampers’ ink into an unexpected black hue. Users are feeling frustrated by this situation and have unsuccessfully tried to resolve it with customer support. We analyze this ink mystery in this blog article, going over the user’s experience, common problems, and possible fixes to bring back the sharpness of DTF prints.

The Problem Explained

I’ve got this Uninet 1000 DTF printer, and it’s throwing me a curveball with one of the white dampers. The ink inside decides to go all mysterious and turns black overnight. Even when I kick off a fresh print with white ink, it comes out more like a gloomy dark grey.

Strangely, it behaves itself for one job, but the moment I dive into the next one, it starts with the black ink shenanigans within minutes. I’ve reached out to the customer service folks, sent them photos and all, but they just keep telling me the same routine, and the problem doesn’t budge. It’s getting seriously frustrating!

The Solutions

Check for One-Way Valves in Dampers:

Replace the damper if it has a one-way valve and you see that the ink is becoming erratic, particularly if there is a rapid shift in colour. If the smooth flow isn’t being ensured by these valves, changing the damper might be the solution to getting things back to normal.

Consider Valveless Dampers:

If your dampers are valveless (lacking one-way valves), the culprit might be a vacuum issue in the ink lines. Repositioning the ink lines attached to each damper might help with troubleshooting. Occasionally, moving them around might affect the flow. Watch for waste ink seeping back into the dampers – this may be the source of the issue.

Analyse Printhead Wet Capping:

Take caution with the fluid levels in the capping station if you are using wet capping for your printheads. A backlog into the dampers from too much fluid here might result in unanticipated variations in the colour of the ink. Modify the wet capping to make sure the system isn’t overloaded. This might fix the waste ink infiltration problem.

Advanced Troubleshooting Techniques

- Check for Air Leaks: Inspect the entire ink delivery system, including hoses and connections, for any signs of air leaks. A little leak might cause problems with the hoover and the ink. Fix any leaks that you find to guarantee a steady flow.

- Analyse Ink Quality: Unexpected colour changes can happen by polluted or low-quality ink. Make sure the ink for your Uninet 1000 DTF printer is what the company recommend. To rule out any issues relating to the ink, think about switching to a new batch.

| Image | Product | Features | Price |

|---|---|---|---|

FOR EPSON PRINTERS  | CenDale Premium DTF Ink 600ML

| 9.9 | Check on AmazonGet 1200ml Pack |

ALL DTF PRINTERS  | Welacer DTF Ink Premium 6x100ml

| 9.8 | Check on Amazon10% Coupon |

AMAZON’S CHOICE  | Enlite DTF Ink 250ML Combo Pack

| 9.6 | Check on AmazonGet 500ml Pack |

WATERPROOF  | LOTSA. STYLE Premium DTF Ink

| 9.5 | Check on Amazon |

EPSON PRINTERS REFILL  | Greenland Office DTF Ink Premium 600ml

| 9.3 | Check on Amazon10% Coupon |

FOR ALL DTF PRINTERS  | Jecqbor DTF Transfer Ink

| 8.9 | Check on Amazon25% Coupon |

- Monitor Ink Temperature: Fluctuations in ink temperature can impact its viscosity, potentially causing flow problems. Verify that the ink temperature is within the printer’s recommended range. To ensure more consistent printing circumstances, think about using a temperature-controlled option.

- Check Printhead and Dampers for Contamination: Look for any evidence of ink residue or contamination on the printhead and dampers. Use the cleaning solution that is suggested to give them a thorough cleaning. Contaminants can disrupt the flow of ink and lead to unexpected color variations.

Don’t Forget These…

- Examine Firmware and Software Settings: Make sure you update the firmware and software on your printer. Verify the damper control and ink circulation settings. Frequently, firmware upgrades come with bug patches that might take care of problems with damper performance and ink flow.

- Seek Community Input: Participate in DTF printing-related social media groups, user communities, and online forums. Talk about your experience and get guidance from experienced users who have probably dealt with same difficulties. Innovative solutions are often produced by pooling expertise.

- Speak with a DTF specialist: If all else fails, think about contacting a technician or specialist in DTF printing. They are able to do a more thorough examination of your particular printer configuration and provide customised advice based on their knowledge.

Remember to document any changes you make during the troubleshooting process, and approach each step methodically to identify and address the root cause of the ink discoloration issue with your Uninet 1000 DTF printer.

Conclusion

These sophisticated troubleshooting approaches helped me solve the mystery of my Uninet 1000 DTF printer’s ink issue. From sealing elusive air leaks to scrutinizing ink quality and temperature, each step contributed to unraveling the mystery.

Even while my difficulties persisted, my prints were given new life by the combined efforts of online communities and careful inspections. This experience highlights the value of rigorous inquiry and pursuing ideas beyond the apparent for people confronting similar ink conundrums. The quest for vibrant, consistent DTF prints continues, armed with newfound knowledge and a resilient spirit.

FAQs

The issue could stem from one-way valve malfunctions in dampers or a vacuum problem in the ink lines. Valve replacement or adjusting the ink line positions might help resolve the unexpected ink color change.

Valveless dampers might require investigating and addressing vacuum issues in the ink lines. Experiment with repositioning the ink lines connected to each damper to troubleshoot the problem.

Excessive fluid in the wet capping system may lead to ink backup into the dampers, causing unexpected color variations. Adjust the wet capping settings to prevent overwhelming the system.

Regularly check for air leaks in the ink delivery system, use high-quality and uncontaminated ink, monitor ink temperature, and inspect the printhead and dampers for any contamination to maintain a steady ink flow.

Engage with online forums, user communities, or social media groups dedicated to DTF printing. Sharing experiences and seeking advice from experienced users can provide valuable insights and solutions.

Ashley Wang is a skilled sales manager with knowledge in DTF printing. She presently works for ShenLan Digital, a reputable DTF printer maker. Ashley is the best person to offer advice on selecting the most suitable DTF printer because she has tested a lot of them. She launched DTFPrinterSchool to educate individuals and organizations about DTF printing technology, providing her expertise and observations on the most recent advancements in the sector. Ashley is an invaluable resource for businesses and individuals wishing to invest in DTF printing technology because of her expertise and experience in the industry.