Set off on a colorful adventure into the world of DTF printing, where accuracy and creativity coexist. Amid the range of options, a subdued obstacle surfaces: the mystery of fading and multicolored stripes upsetting the sophistication of grey patterns. In order to provide you with a customized guide to help you bring back the genuine spirit of solid colors in your DTF printing activities, we discuss how to get rid off mixed color stripes in grey prints in DTF. Let’s explore troubleshooting and find ways to make every print shine.

Problem with Grey Prints

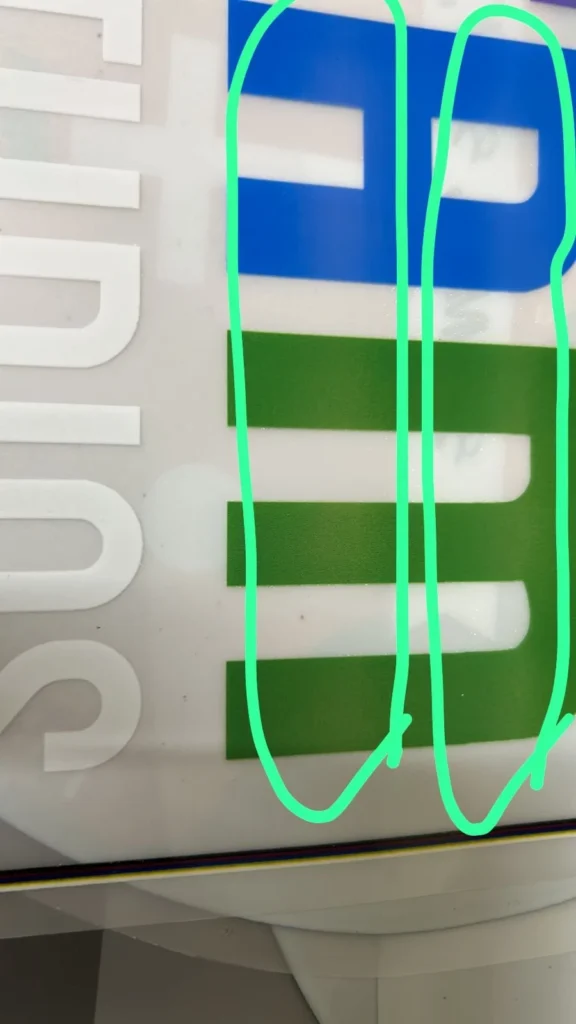

Throughout my considerable DTF printing experience, using Hosonsoft print software and Maintop RIP software, I have come across a recurring issue that has surfaced during otherwise flawless printing processes. The first problem is in designs that use solid colors, where fading stripes are an unwanted guest that ruins the smooth transition between colors.

The second problem is in designs that use gray especially, where there are unsightly magenta streaks that just won’t go away. The issue still exists after intensive attempts, including contacting the dealer, who assiduously investigated a wide range of options, from ICC profile upgrades to a variety of software configuration tweaks. This dilemma has prompted a search for more in-depth understanding and tactical answers in the field of DTF expertise.

Solutions

I’ve successfully navigated a similar challenge in the past, and one effective solution involves a meticulous examination of the PET film. Similar to the problem I just photographed, I too had fading stripes that completely disappeared after the PET film was changed. This little but effective change brought the print quality back to life. Thus, demonstrating the need of a spotless film surface for DTF printing.

A useful solution also entails a brief change in your printing media. In your RIP software options, you can turn off the white ink by choosing to print on plain paper. This stage functions as a diagnostic tool, assisting in determining if the problem continues on a different substrate. Isolating the issue is a calculated step, and in my experience, it has shown possible causes and opened the door for focused remedies.

Furthermore, when you do your printing tasks is really important. I’ve run across identical issues when trying to start printing right away after a cleaning session. To mitigate this, wait a little while after cleaning before starting any printing chores. This little tweak provides a more seamless transition from maintenance to production and reduces the possibility of running into color discrepancies.

Advanced Tips for Color Calibration

As an experienced DTF printing specialist, I’ve discovered that exploring the subtleties of color calibration is necessary to achieve perfect color accuracy. Here are some advanced pointers to improve your color calibration skills:

- Professional Color Profiling Tools and Software: Investing in high-quality color profiling tools and software can significantly enhance your ability to fine-tune color settings. With the help of these tools, you’re able to customize things even further, creating profiles that are unique to your printing configuration.

- Regular Calibration Routines: Make color calibration a routine part of your maintenance schedule. Your printer will continuously generate accurate and brilliant colors over time if you calibrate it on a regular basis. This procedure can be streamlined using automated calibrating equipment to make it effective and hassle-free.

- Collaborate with Suppliers for Custom Color Formulations: Build a cooperative connection with the vendors of your substrate and ink. Collaborate with them to create unique color combinations that are tailored to your particular DTF printing configuration. Superior color matching and overall print quality can be achieved with this customized strategy.

- Explore Advanced Color Management Features: Dive into the advanced color management features available in your RIP software. To adjust the color output, play about with tone mapping, color correction, and other options. Complex settings that are available in some RIP software solutions can have a big impact on getting the right color effects.

More Tips

- Use Cross-Media Color Matching: Take into consideration the properties of additional output devices in your workflow to expand the scope of your color calibration efforts beyond the printer. Consistency across several platforms is ensured by using cross-media color matching, from the digital design stage to the finished printed output.

- Keep an eye on Environmental Factors: Recognize the elements in the environment that might affect how colors are reproduced. The appearance of colors may be affected by temperature, humidity, and lighting. To reduce these fluctuations and ensure consistent color output, keep the environment steady and under control.

- Train Your Team on Color Management Best Practices: Equip your employees with best practices for color management understanding. To maximize color accuracy in DTF printing, provide training on how to make use of color profiling tools. This is for the interpretation of color data, and making well-informed judgments.

You will be able to solve present color issues and set yourself up for greater accuracy and consistency in your DTF printing operations by implementing these advanced ideas into your color calibration plan.

Conclusion

Overcoming the difficulty of fading and mixed-color stripes in grey prints is both an art and a science in the dynamic world of DTF printing. We solved these difficulties using a combination of troubleshooting, substrate examination, and advanced color calibration.

As a seasoned DTF specialist, I urge you to take advantage of these fixes and turn obstacles into chances for flawless printing. Allow your prints to convey a tale of faultless perfection, demonstrating the painstaking artistry that goes into each stroke and color. Take your DTF printing to the next level with assurance and accuracy.

FAQs

Faded stripes often result from issues with the PET film. Consider inspecting and, if necessary, replacing the film to restore seamless color transitions.

Yes, temporarily shifting to plain paper and disabling white ink in RIP software settings can serve as a diagnostic tool. This helps identify whether the problem persists and aids in isolating potential causes.

Allow a brief interval between the cleaning process and initiating printing. This simple adjustment minimizes the likelihood of encountering color inconsistencies post-cleaning.

Absolutely. Invest in professional color profiling tools, establish collaborations with suppliers for custom color formulations, and explore advanced features in RIP software for precise color management. Regular calibration routines and cross-media color matching further enhance color accuracy.

Yes, factors like lighting conditions, humidity, and temperature can influence color appearance. Maintain a stable and controlled environment to minimize these variables and ensure consistent color output.

While ink formulation is crucial, faded stripes are often related to the PET film or substrate. Ensure compatibility and quality in both ink and film for optimal results.

Absolutely. Opt for substrates compatible with DTF technology, ensuring they complement the nuances of grey color. This can significantly impact the quality of prints.

Regular print head maintenance, including cleaning and ensuring proper ink flow, is vital. Unclogged print heads contribute to consistent color reproduction in DTF prints.

Indeed, outdated ICC profiles can impact color accuracy. Regularly update your profiles to align with the latest standards and advancements in DTF technology.

Choosing the right substrate is paramount. Evaluate and select substrates suitable for DTF technology and compatible with grey shades, minimizing the occurrence of faded stripes.

Ashley Wang is a skilled sales manager with knowledge in DTF printing. She presently works for ShenLan Digital, a reputable DTF printer maker. Ashley is the best person to offer advice on selecting the most suitable DTF printer because she has tested a lot of them. She launched DTFPrinterSchool to educate individuals and organizations about DTF printing technology, providing her expertise and observations on the most recent advancements in the sector. Ashley is an invaluable resource for businesses and individuals wishing to invest in DTF printing technology because of her expertise and experience in the industry.