Are you tired of the time-consuming and messy process of powdering your DTF prints? Look nowhere else! For DTF printing lovers like you, the innovative DTF Powder shaker is a game-changer. Its revolutionary design and user-friendly features make powder distribution simple and efficient. Say goodbye to uneven coatings and hello to crisp, vibrant prints! In this article, we’ll learn more about DTF Powder shaker, including its benefits, how to use it, how to keep it in good shape, and real-life examples.

What is DTF Powder Shaker?

DTF Powder shaker is a specialized tool designed to simplify and enhance the powdering process in DTF (Direct to Film) printing. DTF printing is a well-liked technique for applying vivid, full-color animations to a variety of surfaces, such as clothing, ceramics, and more. Using a suitable printer, we print the image on a special film. Then, a powdered glue layer is put over the colored areas. The excess powder is then removed, leaving behind the design for transfer onto the desired substrate.

The DTF shaker machine is an important part of this process. It makes sure that the adhesive powder spreads evenly and precisely on the printed film. It aims to eliminate manual powdering techniques such as sieving and filtering, which are time-consuming, untidy, and result in irregular coatings. The shaker works by evenly dispersing the adhesive powder via regulated vibrations. This produces better image quality and increased transfer effectiveness.

Why Do I need it?

It provides a practical and effective solution for powder distribution and is outfitted with user-friendly features. Typically, it has a power supply, an adjustable shaking mechanism, and a safe holding area for the powdered glue. Users can get professional powder coats in a fraction of the time by putting the printed film inside the shaker and turning on the shaking function.

Due to its capability to speed the powdering process and provide high-quality results, the DTF Powder shaker has grown in popularity among both DTF printing amateurs and experts. Whether you’re a seasoned DTF printer or a newbie trying to streamline your process, the Powder shaker may improve your printing experience.

In the following sections, we will highlight the advantages of utilizing DTF shaker, offer a step-by-step tutorial on its use, address maintenance, and share real-life experiences from individuals who have integrated this revolutionary tool into their DTF printing processes.

Benefits of Using DTF Shaker Machine

Using a DTF Powder shaker in your DTF printing process has a number of important benefits that can improve your general experience and the quality of your prints. Let’s examine the benefits of integrating this cutting-edge instrument into your process:

- Effective and uniform Powder Distribution: The DTF Powder shaker makes sure that the adhesive powder is applied to the printed film in a uniform and constant manner. By using carefully regulated vibrations, its shaking mechanism disperses the powder, eliminating the need for human brushing or sifting. Consequently, the adhesive powder is coated uniformly, lowering the possibility of uneven or blotchy prints.

- Improved Image Clarity and Sharpness: The DTF Powder shaker machine improves the clarity and sharpness of your prints by ensuring a consistent and uniform layer of adhesive powder. The powder sticks uniformly to the inked regions due to the equal dispersion, enabling precise and accurate transfer onto the substrate. This results in printouts with sharper details, bright colors, and a professional appearance.

- Saving time and money: When compared to manual techniques, the Powder shaker drastically cuts down on the amount of time needed to powder your prints. You can quickly apply a uniform powder coating by simply inserting the printed film into the shaker and turning on the shaking function. Because this function saves time, you can be more productive and print more things. Additionally, by eliminating the need for manual brushing or sifting, you save on the cost of additional tools and materials.

- Ease of Use and Reduced Manual Effort: The DTF Powder shakers are user-friendly. Because of its simple operation, both seasoned DTF printers and newcomers can utilize it. We can made professional powder coats with just a few easy steps and don’t require complicated methods or a lot of training. The shaker also reduces the physical labor needed for conventional powdering procedures, making it easier and less likely to make mistakes.

How to Use DTF Powder Shaker Machine?

Using a DTF Powder shaker is a simple process that can make the powdering step in your DTF printing workflow much easier and faster. The following steps will show you how to use it efficiently:

Get the DTF shaker ready:

- Make sure the shaker is clean and clear of any particles or dirt left over from prior uses. This will support preserving the shaker’s efficacy and efficiency.

- Verify that the power supply is connected and operating correctly . Depending on the shaker’s particular model, the power source may be electrical or battery-operated.

Load the Printed Film:

- Obtain the printed film containing the desired design to be transferred to the substrate.

- Carefully place the printed film inside the DTF Powder shaker, ensuring that the inked side is facing up. This will enable the DTF adhesive powder to stick to the regions that have been inked.

Change the Shaking Settings:

- The DTF Powder shaker could have options to change the strength or duration of the shaking. To find the ideal settings for your particular shaker, see the manufacturer’s instructions.

- Adjust the shaking frequency and duration in accordance with your preferences or the manufacturer’s instructions. This will ensure that the adhesive powder distributes uniformly and under control.

Activate the Shaking Function:

- After securing the printed film within the shaker and modifying the shaking parameters, start the shaking function. Depending on the shaker’s layout, you can accomplish this by pushing a button or turning a switch.

- Allow the DTF Powder shaker to operate for the recommended duration. The DTF powder will distribute uniformly across the printed film’s inked regions by the shaking mechanism.

Remove the Printed Film:

- Carefully take the printed film out of the DTF Powder shaker after shaking is complete.

- Gently tap the film to get rid of any extra powder that could have gathered on the regions that weren’t inked. This will increase the likelihood of a precise and clean transfer to the substrate.

Transfer the design:

- Carry out the transfer procedure in accordance with the guidelines designed specifically for your DTF printing system. This typically involves placing the printed film onto the substrate and applying heat and pressure to facilitate the transfer of the design.

Utilizing a DTF Powder shaker to apply uniform and expert powder coatings to your printed films is simple when you follow these procedures. The automatic shaking procedure and the shaker’s user-friendly design remove the need for manual powdering methods, saving you time and effort and delivering excellent results.

Selecting the Right DTF Powder Shaker

Selecting the ideal DTF Powder shaker for sheets is essential to ensuring optimal performance and compatibility with your DTF printing requirements. Here are some factors to consider when selecting one:

- Compatibility: Ensure that the DTF Powder shaker is compatible with your DTF printing setup. The requirements for powder dispersion may vary depending on the types of printers and DTF films used. Verify the shaker’s specs to make sure it is appropriate for your printer and film type.

- Shaking Mechanism: Consider the shaker’s shaking system. Choose a shaker that offers predictable shaking patterns and regulated vibrations. The shaking mechanism should be programmable, enabling you to alter the strength and length of the shaking in accordance with your preferences and the requirements of your prints.

- Powder Capacity and Distribution: Think about how much powder the shaker can hold and how well the powder it can sprinkle. In order to handle your printing volume, the shaker should have a large enough powder storage container. Additionally, make sure the shaker distributes the powder over the printed film consistently and evenly to provide uniform coatings.

- Ease of Use: Select a Powder shaker that is simple to use and manage. The controls and settings should be intuitive and accessible. For optimal comfort and effectiveness when using the shaker, take into consideration its ergonomics, particularly the loading and unloading procedure.

- Build Quality and Durability: Assess the build quality and durability of the DTF shaker. Check if it is made up of high-quality materials that can stand up to regular use and keep working well over time. Look for user testimonials or comments to learn more about the shaker’s dependability and longevity.

- Price and Value: Consider the price of the DTF Powder shaker and assess its value in relation to its features and performance. To discover the ideal compromise between price and quality, evaluate several models and brands. Remember that making an investment in a dependable shaker might eventually lead to more output and better print quality.

- Manufacturer Support and Warranty: Look into the reputation of the manufacturer’s customer service and warranty policies. In the event that there are any issues or concerns with the DTF Powder shaker, a reliable manufacturer will provide sufficient assistance. A warranty ensures protection against any manufacturing defects or malfunctions.

You can pick the best DTF Powder shaker to meet your unique DTF printing needs by considering these criteria and doing extensive research. Read user reviews, compare specs, and ask DTF printing pros for advice before buying.

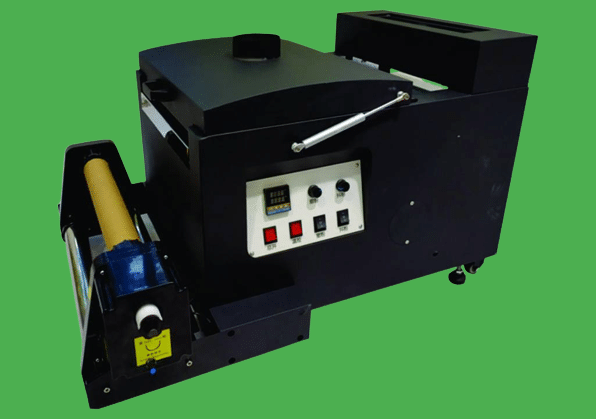

Procolored Powder Shaking And Drying All-In-One Machine For DTF Printer

- Powder conveyor belt

- Automatic air circulation and purification

- Automatic winding film reel

- Control panel:

- a.Shaking speed b.Dust speed c.Temperature regulation

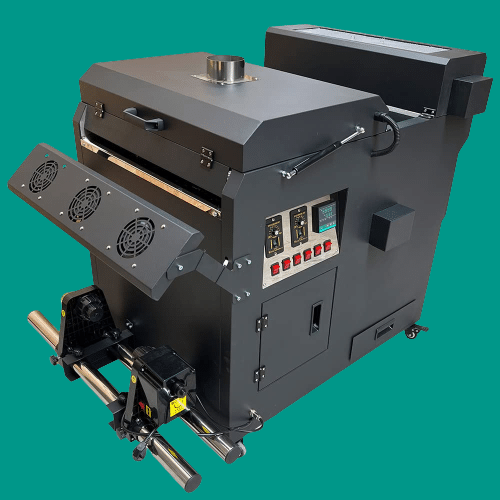

Knight A3+ Powder Shaker & Dryer

- A3+ Powder Shaker with integrated drying and powder shaking

- Fits up to 13″ inches Roll

- Automatic Roll Feeder in the front.

- Nice and compact design

Tips for Maintaining DTF Powder Shaker

Proper maintenance of your DTF Powder shaker is critical to ensuring its durability, constant performance, and dependable powder dispersion. Here are some pointers to keep your machine in good condition:

Regular Cleaning:

- After every usage, clean the DTF Powder shaker to get rid of any leftover adhesive powder or dirt.

- To remove the powder from the shaker’s inner and exterior surfaces, use a soft, dry cloth or brush.

- Pay close attention to any cracks or challenging-to-reach locations where powder residue could collect.

Avoid Contact with Liquids and Moisture:

- Avoid exposing your DTF Powder shaker to liquids and moisture to protect the internal parts.

- To prevent any possible corrosion or electrical problems, store the shaker in a dry, sterile environment.

Lubrication:

- Check the manufacturer’s guidelines to determine if you need lubrication for the shaking mechanism.

- If lubrication is required, follow the specified directions and use a suggested lubricant sparingly.

- Regularly inspect the swaying mechanism for any indications of excessive friction or wear, and address any issues as soon as possible.

Proper Storage:

- When not in use, store the DTF Powder shaker in a secure and dust-free location.

- Avoid placing the shaker in direct sunlight or very hot environments since doing so might shorten its lifetime and damage its ability to function.

- Use the case or cover that the shaker comes with if it has one to protect it from dust and possible harm.

Follow the manufacturer’s instructions:

- Read the manufacturer’s maintenance instructions for your DTF Powder shaker model.

- To maintain optimum performance, follow any unique cleaning, maintenance, or storage requirements given by the manufacturer.

Troubleshooting:

- If your DTF Powder shaker breaks down, see the user manual or call customer service.

- If you don’t have the appropriate skills, stay away from doing any repairs or adjustments yourself.

- Following these maintenance instructions can extend the life of your DTF Powder shaker. Powder distribution will be constant and dependable if you clean, store, and follow the manufacturer’s instructions.

Conclusion

The DTF Powder shaker has changed the way powdering is done in DTF printing. It has many benefits for both hobbyists and pros. It is a game-changer in the world of DTF printing, thanks to its effective and consistent powder dispersion, enhanced image quality, time and cost savings, and simplicity of use. You can enhance your printing by choosing the correct shaker, using it properly, and maintaining it.

FAQs

It is a tool that businesses use in DTF (Direct to Film) printing to evenly distribute adhesive powder onto the printed film for transfer onto the desired substrate.

It operates by using controlled vibrations to disperse the adhesive powder uniformly over the inked areas of the printed film, ensuring even and precise powder coatings.

Using a DTF Shaker machine offers benefits such as efficient and uniform powder distribution, improved image quality, time and cost savings, and ease of use, resulting in professional-looking prints.

DTF Powder Shakers are compatible with various DTF printing setups. However, it is important to ensure that the shaker is compatible with your specific printer and film type. Refer to the manufacturer’s specifications for compatibility information.

No, DTF Shakers are user-friendly and easy to operate. With intuitive controls and simple loading procedures, both experienced DTF printers and beginners can effectively use it.

Yes, many DTF Powder shakers offer adjustable shaking settings, allowing users to customize the shaking intensity and duration according to their preferences and printing requirements.

Ashley Wang is a skilled sales manager with knowledge in DTF printing. She presently works for ShenLan Digital, a reputable DTF printer maker. Ashley is the best person to offer advice on selecting the most suitable DTF printer because she has tested a lot of them. She launched DTFPrinterSchool to educate individuals and organizations about DTF printing technology, providing her expertise and observations on the most recent advancements in the sector. Ashley is an invaluable resource for businesses and individuals wishing to invest in DTF printing technology because of her expertise and experience in the industry.