Are blank pages getting in the way of your DTF printing business and making you and your customers unhappy? Imagine this: Despite your investment in cutting-edge DTF printing equipments, all you receive are blank pages, which is disappointing.

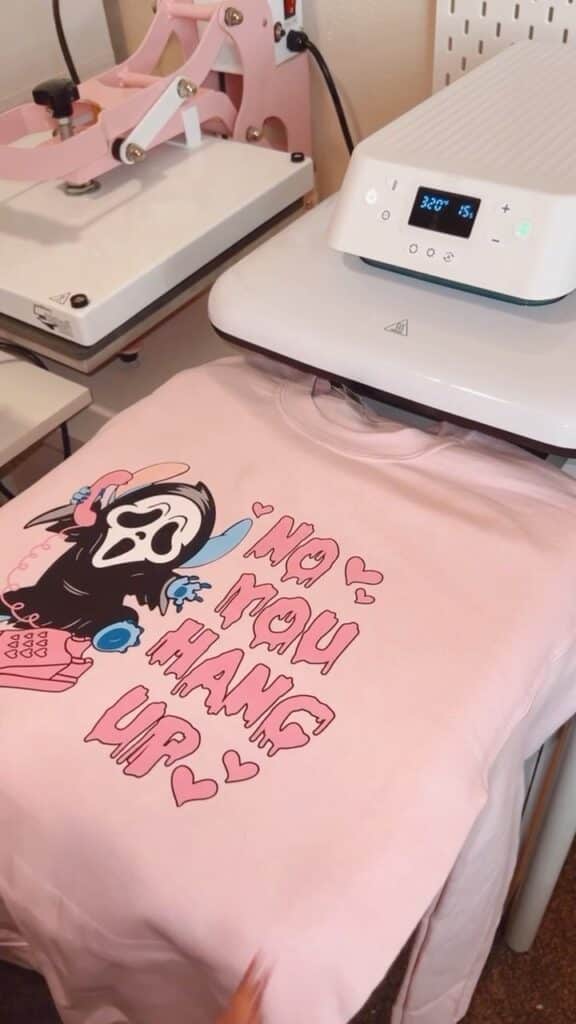

In this guide, we’ll figure out what’s going on with those blank sheets and give you the knowledge and skills you need to solve this frustrating problem and make sure your DTF printing operation goes smoothly. Say goodbye to blank pages and hello to flawless tshirt prints!

Understanding the problem

In my recent experience, I came into a somewhat confusing series of problems with an Epson XP 15000 printer that I had turned into a workhorse for Direct-to-Film (DTF) printing, featuring DTF ink. Let me take you on an exploration of my experiences as a DTF printing specialist.

First, I performed a nozzle check after loading the original cartridges with DTF ink, and the results weren’t very encouraging. White ink was noticeably absent, and several of the colors had painfully broken lines. This definitely wasn’t the outcome I was hoping for.

I made the decision to convert to chipless cartridges in the hopes that it would help me overcome this first hurdle. However, things took a turn for the worse, as the printer started churning out entirely blank pages. To say the least, it was a depressing sight.

Unperturbed, I followed some DTF printing advice and went the debugging path, removing the airflow tabs. I restarted the printer after making this change and carried out another nozzle inspection. I was shocked to see that the issue was still as it was, along with those annoying broken lines and the ongoing lack of white ink.

As if this weren’t difficult enough, a fresh obstacle appeared. I received a maintenance box replacement prompt from the printer. I hadn’t even managed to finish a single DTF print job yet, and it looked like a never-ending succession of obstacles.

These problems were surely confusing and annoying. As a seasoned DTF printing professional, I was aware that these difficulties had to be overcome. To make sure that this Epson XP 15000 DTF conversion would produce the high-quality outputs it was capable of producing, I was determined to identify the underlying issues and discover the appropriate solutions.

Fixing Blank Page Issues

Let me share my expert insights on how to tackle the challenges I have encountered with the Epson XP 15000 converted DTF printer:

Examine and Clean Printhead

I started by carefully examining and cleaning the printhead. This is a basic upkeep activity that often fixes problems like broken lines and ink shortages. A thorough nozzle inspection and an appropriate printhead cleaning method performed in accordance with the printer’s instructions showed a noticeable improvement. It made sure that the ink flow was unhindered, and the print quality significantly increased.

Check Ink and Printhead

Next, I made sure the ink and printhead were working properly. To get the best effects, we must use premium DTF inks vs non-genuine inks. It was essential to make sure the ink cartridges were appropriately placed and fastened within the printer. This procedure reduced ink installation complications and streamlined printing.

Also See: Fixing vertical stretches in DTF printing

Ensure White Underbase

A bright and accurate print depends on having a strong white underbase when printed on materials with transparent or light backgrounds. A crucial change was making the printer settings incorporate this white underbase before printing other colors. It improved print quality and solved the issue of missing white ink, especially on such substrates.

Check Software and Connectivity

Verifying the software and connectivity was another vital component of my troubleshooting journey. It was vital to make sure the printer was connected properly and that the appropriate printer software and drivers were successfully loaded on my computer. By completing this step, the printing process will not interrupt by any software- or connectivity-related problems.

Last but not least, I responded to the maintenance box replacement prompt that had shown. It was simple yet essential to change the maintenance box according to the manufacturer’s instructions. This part controls the disposal of used ink, and a broken or overfilled box might impair print quality. By replacing it, I effectively resolved this issue and ensured the printer’s smooth operation.

Preventing Future Blank Page Printing Problems

Maintaining your DTF printer’s efficiency and dependability requires preventing blank page printing issues. Here are some proactive measures you can take as a DTF printing professional to guarantee a seamless and problem-free DTF printing experience:

- Regular Maintenance Schedule: Create a schedule for regular printer maintenance. Check for obstructions, clean the printhead often, and change the ink cartridges as necessary. Regular maintenance helps stop problems from developing in the first place.

- Proper Ink Handling: Take caution while handling DTF ink. Keep it away from strong sunlight and severe temperatures in a cool, dry location. To avoid contamination or evaporation, ensure that ink cartridges are firmly sealed. For reliable printing results, it is crucial to use new, premium ink.

- Testing the Substrate: Test your selected substrate to make sure it works with your DTF printer before beginning a print job. Depending on the material, the ink settings or drying time may need to be changed. Testing the substrate helps avoid wasting prints and supplies.

- Ink Usage Monitoring: Keep an eye on your ink use and replace empty ink cartridges as needed. Blank pages and wasted resources result from running out of ink mid-print. Create a mechanism to monitor ink levels and place orders for more supplies as necessary.

- Quality Control Procedures: For each print job, implement quality control checks. After printing a sample, look it over for any problems like missing ink or inconsistent color. Before starting the whole print run, make any required adjustments to the settings or maintenance processes.

Conclusion

In conclusion, you can assure smooth and consistent DTF printing by diagnosing blank page printing difficulties and taking preventative steps. You’ll be better able to produce high-quality output and avoid the annoyance of blank pages with routine maintenance, correct ink management, and a well-controlled printing environment. To sustain the brilliance of your DTF printing initiatives, be cautious & keep your equipment updated.

FAQs

Some of the most common reasons are jammed printer needles, wrong ink settings, problems with the media or substrate, and software or system issues.

To maintain your DTF printer in top shape, I advise you to develop a regular maintenance routine, often weekly or before each big print job.

Yes, printing issues such as blank pages can happen when using DTF ink that is of poor quality or has expired. Utilizing top-notch, recent ink from reliable vendors is crucial.

Ink flow and print quality could be affected by extremes of temperature and humidity. Stable printing conditions within manufacturer recommendations help ensure consistent results.

Getting assistance from a qualified DTF specialist or the printer manufacturer’s support staff is vital in addressing persistent difficulties if you’ve exhausted DIY troubleshooting techniques.

To avoid disruptions during print jobs, set up an ink consumption monitoring system to keep track of ink levels and place advance orders for supplies.

Maintain thorough records of all maintenance procedures, troubleshooting techniques, and effective print settings. This material is a useful resource for resolving current problems and identifying abnormal patterns.

Switching to chipless cartridges may help, but be sure they work with your printer and that other difficulties aren’t the cause.

Deep cleaning uses a lot of ink, so use it conservatively. Preventive maintenance usually just requires routine printhead cleaning.

Ashley Wang is a skilled sales manager with knowledge in DTF printing. She presently works for ShenLan Digital, a reputable DTF printer maker. Ashley is the best person to offer advice on selecting the most suitable DTF printer because she has tested a lot of them. She launched DTFPrinterSchool to educate individuals and organizations about DTF printing technology, providing her expertise and observations on the most recent advancements in the sector. Ashley is an invaluable resource for businesses and individuals wishing to invest in DTF printing technology because of her expertise and experience in the industry.